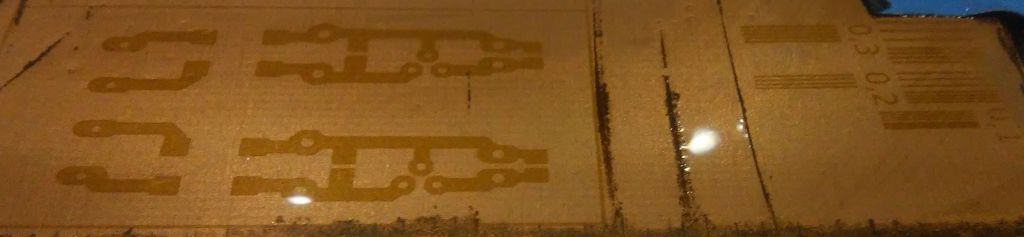

The PCB:

A scrap piece of 5+ year old UV sensitive PCB. The sticky black residue on the PCB is the clue from the protective foil.

The mask:

Transparent foil for laser printers. Printed on Samsung CLP-320 in greyscale mode. Single layer.

The traces:

- 0,1 mm with the gap of 0,1 mm

- 0,1 mm with the gap of 0,2 mm

- 0,2 mm with the gap of 0,2 mm

- 0,2 mm with the gap of 0,3 mm

- 0,2 mm with the gap of 0,4 mm

- 0,3 mm with the gap of 0,2 mm

- 0,3 mm with the gap of 0,3 mm

- 0,2 mm with the gap of 0,6 mm

The rest of the PCB will be used for the rectifier circuit.

The UV cycle:

- preheat lamps for 3 minutes

- exposure for 6 minutes

The developer:

DP 50 (probably 🙂 @ 20°C, no agitation

Rinse

Use running water.

After the developing, traces of 0,1/0,1 mm are seen as solid.

Seem like PCB got some unintentional light on the upper left corner?

Etcher:

Sodium persulfate @ 25°C, constant manual agitation. Too cold, thus took too long to etch the copper layer.

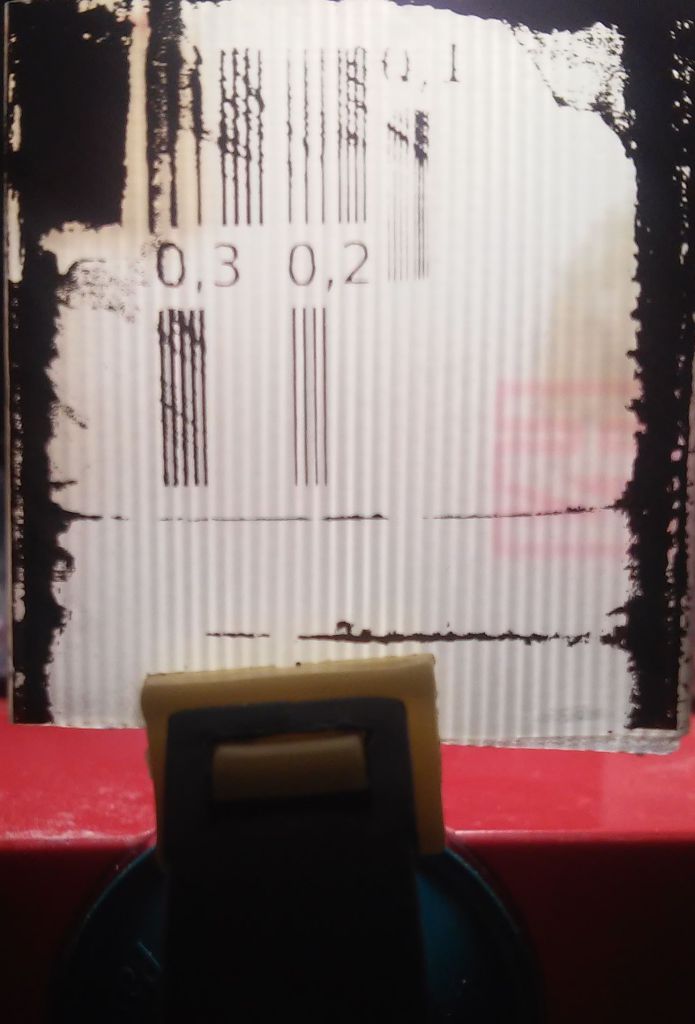

After the etch bath:

Definitely there is a problem with the transparent exposure pad. Scratches are all over the upper traces.

- traces of 0,1 / 0,1 mm are not continuous and too narrow;

- traces of 0,1 / 0,2 mm are not continuous and too narrow;

- traces of 0,2 / 0,2 mm are too narrow;

- traces of 0,2 / 0,3 mm are too narrow but almost perfect;

- traces of 0,2 / 0,4 mm are too narrow;

- traces of 0,3 / 0,2 mm are too narrow but of acceptable quality;

- traces of 0,3 / 0,3 mm are slightly “washed out” but of acceptable quality;

- traces of 0,3 / 0,6 mm are of different widths and slightly “washed out”;

Rants:

- Get rid of the current exposure plate.

- Preheat the developer up to 20-25°C and keep the temperature constant;

- Preheat the etcher up to 40-42°C and keep the temperature constant. Are there any indirect heaters available?

- Agitate the etcher. Need to search for magnetically coupled plastic pump on the eBay.

- Place a mate UV unifying media between the lamps and the PCB.

- Clean the PCB after removing the foil. The glue stick everywhere …

- Traces of 0,2/0,1 mm are worth trying. Expect them to appear as 0,15/0,15 mm on the PCB. For this i will need constant and turbulent agitation system. Laminar flow will probably overetch the parallel traces.